|

Thirty years ago, Bill Smith established Lincoln Sewer & Drain after losing his job as a welder. He worked briefly for a relative cleaning sewer lines and decided that this would be a way to support his young family.

The economy at the time was in the tank: Interest rates in double digits, unemployment at 15 percent, gasoline in short supply. It was an interesting time to start a business, but Smith saw that he could offer a needed service, and that having the best equipment would establish his company with loyal customers who would stick with him when the recovery came.

That is pretty much how things unfolded. Along the way, Smith added pipe bursting, cured-in-place pipe (CIPP) lining, TV inspection and jetting, always with a determination to find the best technology to do the job properly.

Today, the company, based in Mishawaka, Ind., splits its business about equally between plumbing and the diverse lineup of pipe cleaning and repair services. Its inspection and trenchless technologies account for about five percent of the work, but 15 percent of the revenue.

Finding the best

I started out with a Spartan 1065 cable machine after doing some investigating and getting some sound advice, Smith says. After 15 years, he was working 10 to 12 hours a day with one employee. Around that time, he added plumbing to the mix.

Then he attended the Pumper/Cleaner Environmental Expo in Nashville and was one of the first to see a pipe-bursting demonstration, put on by TRIC Tools Inc. Smith and his wife Lisa studied the process carefully, then took the plunge and purchased the HPLS 20 Series bursting system. They have been using it ever since.

Smith says he relies on guidance from his distributor when deciding on an important piece of equipment, but he takes it a good bit further. He looks not for the best price but for the best equipment for the task.

I just think of all the trouble I will have a few years down the road if I do not buy the very best, Smith says. I can see trying to save money, and then later kicking myself because I was stupid. The best resolution when you are deciding to make an investment is to talk to other people who are doing the work. People like to talk. Most people will tell you the truth about something like this.

It was five years ago that Smith added CIPP lining. Again he took his time, talking for three years with Nu Flow Technologies Inc., before buying that system. The company found CIPP a necessary alternative for jobs not suited to pipe bursting.

Smith also added a dual tank trailer jetter (18-gpm/4,000-psi) from Harben Inc., with two 300-gallon water tanks. We have had it nine years now, and we have never had to change a hose; never had a pump problem, Smith says. We do regular maintenance. We change the oil and the filters. The unit has logged 900 operating hours.

The company uses three standard color inspection cameras are SeeSnake units by RIDGID.

The three service vans are 2001 Ford E-350s, and as their mileage exceeded 120,000, Smith was thinking of replacing them. At about 140,000 to 150,000 miles, we start having problems, and we get rid of them, he says.

Straight shooter

Smith is adamant about the importance of a distributor who is a straight shooter when it comes to advice on equipment. He has relied on Marvin Frank of Allan J. Coleman in Chicago.

You need someone who is not just trying to make a sale, but will tell you what is the best way to go about doing a specific type of work, Smith says.

Before I bought my first machine, I researched all the distributors to find the person I wanted to work with. A good distributor will know about the companies he is representing. If there is a problem, if you are unhappy about something, you can let the distributor know, and they will get the information to the manufacturer. They all want to keep you happy.

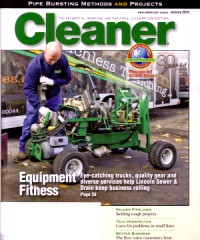

Smith is especially proud of the service vans that make a colorful and distinctive statement as they travel their routes. My service vans are black, says Smith. Our color scheme on our logo, with purple, lime green, bright yellow, and forest green, really stands out. Using black is the opposite of what everybody else is doing. My vans say "Wow!"

Maintenance of the vans and all equipment is handled in-house, though major repairs are sent to a nearby shop. Equipment care is part of the technicians job. Smith expects them to do as he does: wipe equipment down after each use and keep the trucks clean and well stocked.

|